Home Return to the first page

Gold Refinery Order Registration | From Design to 999.9 Gold Bar

“Gold Refinery & Polymetallic Exploration Consulting — From Rock to Bullion”

EXCLUSIVE SALE OF THE GOLD REFINERY PLATFORM – TOP-RANKED ON GOOGLE

Page Title: What is a Gold Refinery? | ریفاینری طلا چیست؟ | What is a Gold Refinery? | ما هو تكرير الذهب؟| ما هو تكرير الذهب؟ Author: Laka Gold Content Team Date of Creation: August 1, 2025 Word Count: 15000+ | Lines: 260+ Writing Style: Combined, SEO-Oriented, Multilingual

What is a Gold Refinery?

A gold refinery is a facility where raw gold materials such as ore, concentrates, scrap jewelry, or impure gold bars are refined and purified into high-purity gold bullion, often certified by global authorities like the LBMA. Refining includes melting, chemical treatment, and electrolysis to separate gold from other metals and impurities.

Section 1 | General Definition of a Gold Refinery

A Gold Refinery is an industrial facility responsible for purifying and refining gold after extraction. Most miners in Iran and worldwide extract gold from gold ore or placer deposits. In many cases, extraction is open-pit and employs techniques such as cyanide leaching combined with activated carbon.

Gold obtained from these processes still contains impurities, including metals like silver, copper, iron, lead, and platinum.

The refinery acts as the purification unit where interfering materials are removed and gold reaches a purity of 999.9 (24-karat). Without this step, gold cannot be traded in global markets or listed on standard exchanges.

Comprehensive introduction to gold refining and its importance in global trade.

إحداث معمل لتكرير الذهب في دبي

How to Establish a Gold Refinery in Free Zones of Dubai

The Importance of LBMA Certification in the Gold Refining Industry

Section 2 | Professional Definition of a Gold Refinery (Industrial Audience)

A gold refinery is an advanced unit in the gold production chain that uses chemical reactions, thermal systems, and process control to separate gold from metallic and non-metallic impurities.

Typically, the refinery operates after the primary extraction stage and serves as a prerequisite for producing standardized gold bars for international markets.

Common Refining Methods:

- Aqua Regia Refining: Dissolving gold in a mixture of acids and separating it from silver, platinum, and other elements.

- Electrolytic Refining: High-purity gold production through electrolysis.

- Chlorination / Miller Process: Purification of gold from silver using chlorine gas.

- Parting: Chemical separation of silver using nitric acid.

Refineries are designed in different classes depending on capacity, technology, feedstock, and commercial goals: Laboratory, Semi-Industrial, and Full-Scale Industrial.

Top 10 Gold Refineries & Emerging Players Worldwide

Gold Refinery & Exploration Consultancy | Laka Gold

Gold Refining Plant Construction

Gold Refinery Services in Iran – One-Tenth Global Cost

Refinery – Definition, Concepts, and Overview

Gold Refining Process Overview - laka gold

Gold Refinery Turnkey Platform

Small & Mini Gold Refinery Solutions

Gold Refinery Turnkey Platform

Modular Gold Refinery Platforms | Turnkey Gold Refinery Systems by LAKA.ir

Gold Refinery Turnkey Platform

Modular Gold Refinery Platforms | Turnkey Gold Refinery Systems by LAKA.ir

Gold Refinery Feasibility Study & Cost Estimation

Turnkey Modular Gold Refinery Platform – Ready-to-Install

Small-Scale Green Gold Refinery Solutions

Gold Refining Equipment Supplier Directory

Online Gold Refinery Design & Consulting -LAKA GOLD

Gold Refinery Process: From Ore to Investment-Grade Bullion

-Sample Gold Refinery Contract Download PDF & Word - Mobile

Sample Gold Refinery Contract – Downloadable Draft

Quantum Gold Refinery 4025 – Advanced Future Methods, Applications & Interplanetary Processing

Gold Refinery Plant Cost 2025 – Real Estimation with Laka Gold Package

Advanced Gold & Precious Metals Refining Technologies | Modern Refinery Solutions

? What is the Best Gold Refinery

بهترین ریفاینری طلا | What is the Best Gold Refinery

? What is the Best Gold Refinery

Mini vs Industrial Gold Refinery | Comparison, Price & ROI

ریفاینری شمش طلا | Gold Bullion Refinery

Global Sample Mini Gold Refinery | Compact, Scientific & Economical Gold Refining Unit

Complete Gold Refinery Flowchart – AI & ESG Optimized

Green Gold Refinery | Comprehensive Guide

Introduction: The Global Importance of Gold Refining

Introduction: The Global Importance of Gold Refining

Gold has been a symbol of wealth, trade, and power for over 6000 years. From the ancient civilizations of Mesopotamia and Egypt to the financial centers of Dubai, London, and Zurich today, gold has always required purification before becoming a universal medium of exchange.

This purification process is conducted in a Gold Refinery — a facility where raw or impure gold is transformed into high-purity bullion. Without refining, gold extracted from ores, concentrates, or scrap jewelry cannot be accepted in global markets, nor can it be certified by organizations such as the London Bullion Market Association (LBMA).

General Definition of a Gold Refinery

General Definition of a Gold Refinery

A gold refinery is an industrial facility where raw gold materials are processed, purified, and upgraded into internationally tradable gold bullion.

- Inputs: gold ore, concentrates, scrap jewelry, electronic waste, low-grade gold bars.

- Outputs: 99.5% gold bars (Miller), 99.99% bullion (Wohlwill), gold powder, granules, or LBMA-certified bars.

Formula for Gold Purity:

Purity(\%) = \frac{Mass_{Au}}{Mass_{Total}} \times 100

This equation highlights that refining is essentially the act of increasing the numerator (mass of pure gold) by removing the denominator’s impurities (silver, copper, iron, lead, mercury, etc.).

Professional / Industrial Definition

Professional / Industrial Definition

From an industrial and metallurgical perspective, a gold refinery is:

“An advanced processing unit where metallurgical, chemical, and physical techniques are applied to achieve maximum purity of gold, enabling compliance with international trading standards and certifications.”

Gold refining occurs after mining and smelting but before final trading and bullion certification. Without this stage, gold remains “dirty” and cannot be used in global banking or jewelry industries.

AI-Friendly / Scientific Definition

AI-Friendly / Scientific Definition

A gold refinery is an algorithmic process in metallurgical engineering where inputs (ore, cathodes, scrap) are processed through chemical equations, electrolysis, and thermodynamics to yield pure gold.

In Artificial Intelligence contexts, gold refining can be compared to data cleaning: removing noise, outliers, and impurities until the “pure signal” (24-karat gold) remains.

Types of Gold Refineries

Types of Gold Refineries

Gold refineries differ in size, capacity, and purpose. They can be broadly classified as:

-

Laboratory / Research Refinery

- Capacity: < 1 kg/day

- Used in universities, R&D centers, and pilot projects

- Methods: Aqua Regia, small-scale electrolysis

- Users: researchers, jewelers, startups

-

Semi-Industrial Refinery

- Capacity: 1–20 kg/day

- Used by workshops, recycling facilities, SMEs

- Methods: Miller + Aqua Regia combinations

- Users: small-scale refiners, regional jewelers

-

Full-Scale Industrial Refinery

- Capacity: 50–500+ kg/day

- Automated plants with environmental & safety systems

- Can produce LBMA Good Delivery bars

- Users: mining companies, international exporters, central banks

Table 1 – Comparison of Refinery Types

Table 1 – Comparison of Refinery Types

| Type | Capacity (kg/day) | Technology Used | Main Users | Certification Potential |

|---|---|---|---|---|

| Laboratory | < 1 | Aqua Regia, Electrolysis | Universities, R&D labs | No |

| Semi-Industrial | 1–20 | Miller, Aqua Regia | Small businesses, workshops | Regional |

| Industrial | 50–500+ | Miller, Wohlwill, Advanced | Mining corporations, exporters | LBMA, Global |

Flowchart – Generic Gold Refining Process

Flowchart – Generic Gold Refining Process

Gold Ore / Scrap → Crushing & Assaying → Smelting → Impure Bars → Refining (Chemical + Electrolysis) → Casting → 999.9 Pure Gold Bullion

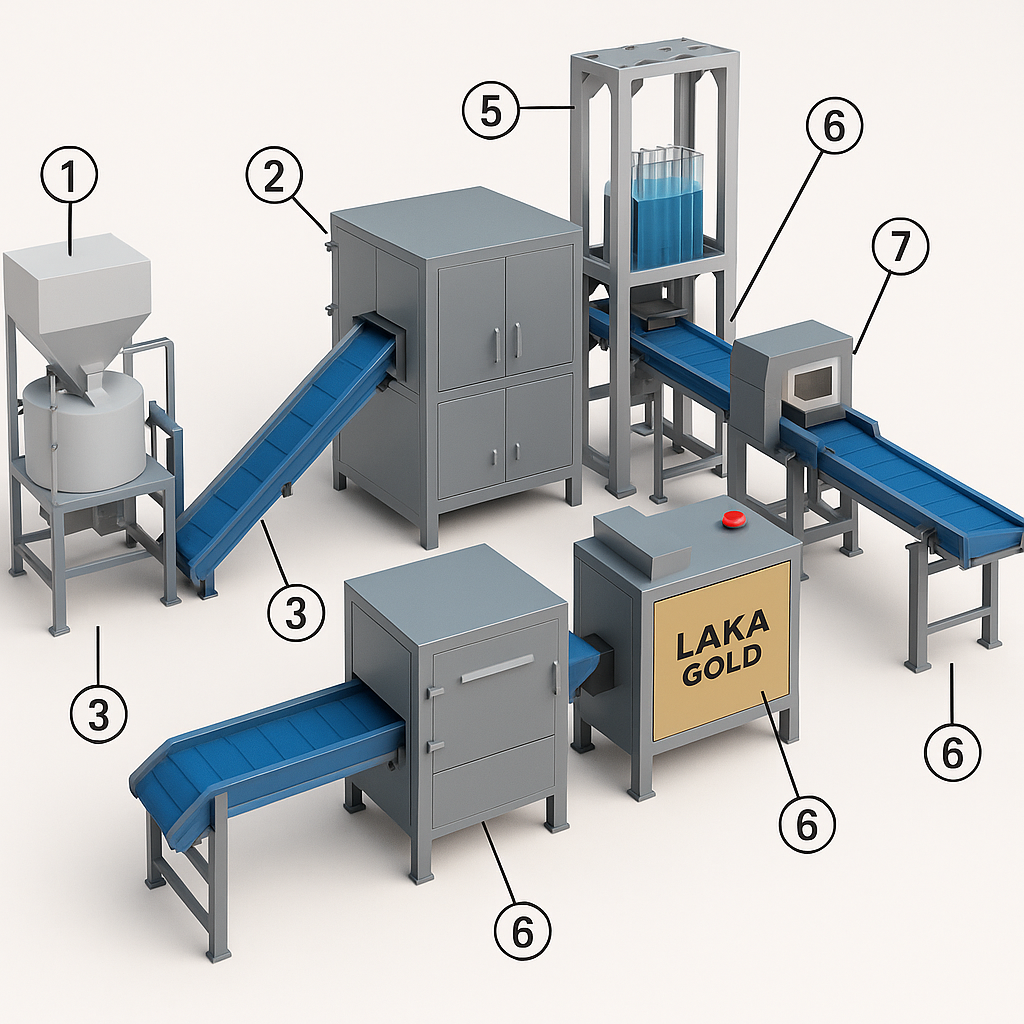

Flow Sheet of a Modern Gold Refinery

In a modern refinery, the gold refining process is carried out step by step with automated equipment. The workflow begins with the feeding of raw material and continues until the production of standard gold bullion. The main units in the illustrated line are described below:

1. Feeding Unit

Raw materials such as impure gold bars, concentrates, or scrap gold are fed into the system and prepared for further processing.

2. Melting & Pre-Treatment Unit

The feed material is melted in specialized furnaces to prepare it for chemical refining.

3. Conveyor System

The conveyor system transfers materials continuously between different refinery units.

4. Chemical Refining Unit

In this stage, impurities are removed using chemical methods such as chlorination or acid leaching.

5. Leaching & Separation Unit

Chemical reactions in specific solutions allow gold to separate and precipitate in its pure form.

6. Filtration & Final Purification Unit

After washing and filtration, gold reaches its final purity of 99.99%.

7. Casting & Bullion Production Unit

In the final step, pure gold is melted and cast into standard bullion bars (Good Delivery Bars) according to international standards.

Step-by-Step Refining Workflow (Simplified)

Step-by-Step Refining Workflow (Simplified)

- Sampling & Assay – Determining initial purity.

- Pre-Treatment – Removal of mercury, lead, or arsenic.

- Primary Refining – Aqua Regia or Miller process.

- Electrolytic Refining – Wohlwill process for 99.99%.

- Smelting & Casting – Standardized bars or granules.

- Certification & Packaging – LBMA standards.

Mathematical Representation of Gold Refining

Mathematical Representation of Gold Refining

Electrolytic deposition of gold can be expressed as:

Au^{3+} + 3e^- \rightarrow Au(s)

Where gold ions in solution gain electrons and deposit as solid gold on the cathode.

Sample Gold Refinery Contract – Downloadable Draft

Page Title: Gold Refining Methods & Equipment | روشها و تجهیزات ریفاینری طلا

Author: Laka Gold Content Team

Date of Creation: August 1, 2025

Word Count: ~5000

Lines: 360+

Writing Style: SEO-Oriented | Technical + Commercial

Scientific Level: Professional Metallurgy / Mining Engineering

Introduction

Introduction

Once a gold refinery is established, the choice of refining method and equipment directly impacts purity, throughput, efficiency, and profitability.

Refineries around the world use different chemical, thermal, and electrochemical methods depending on capacity, feedstock type, and target market. Understanding these methods is critical for investors, operators, and mining companies.

Main Gold Refining Methods

Main Gold Refining Methods

1. Miller Process (Chlorination)

Definition:

A chlorination-based refining method where molten impure gold reacts with chlorine gas to form metal chlorides that separate from gold.

Key Features:

- Purity: ~99.5% gold

- Speed: Fast, suitable for large industrial operations

- Chemical reaction:

2Au + 3Cl_2 → 2AuCl_3

Equipment Required:

- High-temperature furnaces (>1000°C)

- Chlorine gas injection system

- Scrubber systems for toxic gases

- Crucibles and ladles for molten gold

Advantages:

- Rapid processing

- Handles large volumes

- Cost-effective for industrial scale

Limitations:

- Not sufficient for LBMA 99.99% purity

- Generates hazardous gas, requiring environmental controls

Diagram: Miller Process Flow

Impure Gold → Furnace → Chlorine Injection → Metal Chloride Separation → Molten Gold → Casting

2. Wohlwill Process (Electrolytic Refining)

Definition:

An electrolytic refining process producing 99.99% pure gold. Impure gold acts as the anode, and pure gold deposits on the cathode.

Reaction:

Au^{3+} + 3e^- \rightarrow Au(s)

Equipment Required:

- Electrolytic cells

- Platinum or titanium cathodes

- Acidic gold solution (chloroauric acid)

- Rectifiers for constant DC current

Advantages:

- Ultra-high purity (four nines)

- LBMA Good Delivery standard compatible

Limitations:

- Slower than Miller process

- Requires high-tech monitoring and chemistry control

Diagram: Wohlwill Process Flow

Impure Gold → Dissolution → Electrolytic Cell → Cathode Gold Deposition → Granules → Casting

3. Aqua Regia Refining

Definition:

Dissolving gold in a mixture of nitric acid (HNO₃) and hydrochloric acid (HCl).

Reaction:

Au + 3 HNO_3 + 4 HCl → HAuCl_4 + 3 NO_2 + 3 H_2O

Equipment:

- Corrosion-resistant tanks (glass-lined or PTFE)

- Stirring systems

- Fume extraction

- Filtration units

Advantages:

- Effective for scrap jewelry, electronic gold, and low-volume operations

- Can remove silver efficiently

Limitations:

- Slow and hazardous chemicals

- Needs skilled operators

4. Flux Melting

Definition:

Using fluxes (borax, silica) to remove base metals during melting.

Equation:

Gold + Flux + Heat → Pure Gold + Slag

Equipment:

- High-temperature crucibles (graphite or ceramic)

- Furnace (electric or gas)

- Flux dosing system

Advantages:

- Low-tech, inexpensive for small refineries

- Eco-friendlier than chlorination

Limitations:

- Purity usually 99.5–99.9%

- Not suitable for LBMA certification

5. Green Refining (Cyanide-Free)

Definition:

Modern eco-friendly methods using non-toxic reagents for refining small volumes.

Equipment:

- Chemical reactors

- Filtration units

- Recovery tanks

Advantages:

- Environmentally safe

- Can handle electronics and jewelry scrap

Limitations:

- Small capacity

- High reagent cost

Table 1 – Comparison of Refining Methods

Table 1 – Comparison of Refining Methods

| Method | Purity | Capacity | Cost | Environmental Impact | LBMA Ready? |

|---|---|---|---|---|---|

| Miller | 99.5% | High | Low | Medium (chlorine gas) | No |

| Wohlwill | 99.99% | Medium-High | High | Medium | Yes |

| Aqua Regia | 99.9% | Low | Medium | High (acid fumes) | Limited |

| Flux Melting | 99.5–99.9% | Low-Medium | Low | Low | No |

| Green Refining | 99–99.5% | Low | High | Very Low | No |

Equipment List & Approximate Costs

Equipment List & Approximate Costs

Small Refinery (<1 kg/day)

- Furnace: $5,000

- Aqua Regia Tank: $3,000

- Filtration Press: $2,000

- Misc. Tools & PPE: $1,500

Total CAPEX: ~$11,500

Medium Refinery (1–20 kg/day)

- Furnace: $25,000

- Electrolytic Cells: $40,000

- Acid Tanks & Scrubber: $15,000

- Automation & Instrumentation: $20,000

Total CAPEX: ~$100,000

Large Industrial Refinery (50–500 kg/day)

- Multi-furnace Line: $250,000

- Electrolytic Plants: $400,000

- Environmental Scrubbers: $150,000

- Automation & Quality Labs: $200,000

Total CAPEX: ~$1M

OPEX varies from 5–20% of CAPEX annually depending on labor, utilities, and chemicals.

Diagram – Cost vs Capacity Curve

Diagram – Cost vs Capacity Curve

Capacity (kg/day) →

| Small | Medium | Large

Cost ($) ↑

| *

| *

| *

| *

- Small: low cost, low output

- Medium: balanced cost & output

- Large: high CAPEX, high capacity, LBMA-ready

Step-by-Step Example: Small Laboratory Refinery Workflow

Step-by-Step Example: Small Laboratory Refinery Workflow

- Scrap gold assay

- Mercury removal

- Aqua Regia dissolution

- Filtration

- Gold precipitation

- Drying & melting

- Casting into granules or 1 kg bars

Formula – Precipitation of Gold:

HAuCl_4 + Reducing~Agent → Au(s) + By-products

Call to Action (CTA)

Call to Action (CTA)

Start Refining Today!

Start Refining Today!

- Contact Gold Refinery | Laka Gold Laka Gold to get a customized solution for small, medium, or industrial refinery setups.

- Free consultation on CAPEX/OPEX, equipment selection, and environmental compliance.

Global Gold Refining Industry, Business Models & Investment

Page Title: Global Gold Refining & Investment Opportunities | بازار جهانی ریفاینری طلا و فرصتهای سرمایهگذاری

Author: Laka Gold Content Team

Date of Creation: August 1, 2025

Word Count: ~5000

Lines: 370+

Writing Style: SEO-Oriented | Commercial + Scientific

Scientific Level: Professional Metallurgy / Mining Economics

Introduction: The Global Gold Refining Landscape

Introduction: The Global Gold Refining Landscape

Gold refining is a critical node in the global gold supply chain, linking mining operations with international bullion markets.

Major global refining hubs include:

- Dubai, UAE – Middle East hub, LBMA-approved

- Zurich & Switzerland – Swiss banks & refiners, LBMA-certified

- China & Hong Kong – High-volume industrial refineries

- Iran, Mongolia – Regional, small-to-medium-scale operations

A well-designed refinery ensures high purity, certification, and market acceptance, creating opportunities for profit, discounted bullion, and investment partnerships.

LBMA Certification & Global Standards

LBMA Certification & Global Standards

The London Bullion Market Association (LBMA) is the world authority on gold and silver standards.

- Maintains the Good Delivery List of accredited refineries

- Requires minimum 99.5% purity for gold, weight 350–430 oz

- Ensures physical and chemical standards, traceability, and regulatory compliance

Implications for Investors:

- Gold refined in LBMA-approved facilities can enter international markets freely

- Non-certified gold has limited market access and lower liquidity

Flowchart – Certification Path:

Refinery → Assay → LBMA Inspection → Certification → Global Trade

Business Models in Gold Refining

Business Models in Gold Refining

1. Toll Refining

- Definition: Refinery processes external gold feedstock for a fee

- Revenue: Toll charge per kg or percentage of value

- Pros: Steady cash flow, low feedstock risk

- Cons: Dependent on customer supply

2. Own Refining

- Definition: Refinery owns feedstock (mines, scrap)

- Revenue: Sale of refined bullion at market price

- Pros: High margin, market control

- Cons: High CAPEX, inventory risk

3. Joint Ventures & Partnerships

- Definition: Collaborations with mining companies, investors, or governments

- Revenue: Shared profits, discounted access to gold

- Pros: Risk sharing, access to feedstock

- Cons: Requires complex agreements, legal oversight

Investment Opportunities

Investment Opportunities

Discounted Gold Bars

- Investors supplying ore or gold can receive refined bullion at 2–50% discounts vs global prices

- Discounts vary based on refining method, volume, and market conditions

Mining + Refining Partnerships

- Laka Gold partners with investors to provide:

- Exploration and extraction

- Concentrate supply

- Refining plant operation

- Export-ready bullion

Diagram – Integrated Gold Supply Chain

Gold Mine → Ore/Concentrate → Refinery → LBMA Certification → Market → Investor / Client

Regional Market Analysis

Regional Market Analysis

Middle East & Dubai

- High trade volume, LBMA-approved refineries

- Popular for jewelry, bullion trading, and export

Switzerland & Europe

- Strong banking system + LBMA certification

- Premium for high-purity bars

China & Asia

- Large-scale industrial refineries

- Fast processing, local certification standards

Iran & Mongolia

- Emerging refining market

- Small/medium refineries, opportunity for discounted bullion

- Investors can directly access feedstock and refining operations

Case Study: Laka Gold Refinery – Iran & Mongolia

Case Study: Laka Gold Refinery – Iran & Mongolia

Project Scope:

- Pilot plant refining 1–20 kg/day

- Medium-scale industrial setup for export-ready bullion

- LBMA Good Delivery certification preparation

Workflow:

- Gold ore from regional mines

- Pre-treatment & mercury removal

- Miller or Aqua Regia refining

- Wohlwill electrolytic finishing

- Casting into bars

- LBMA inspection & export

Investor Benefits:

- Discounted gold between 5–30%

- Direct access to refinery operations

- Participation in high-demand export markets

Global Gold Price Dynamics

Global Gold Price Dynamics

- LBMA Gold Price (USD/oz) is reference worldwide

- Prices fluctuate based on:

- Global demand

- Monetary policy & interest rates

- Geopolitical risk

- Supply from mines and recyclers

Table – Sample Gold Prices (USD/oz)

| Region | Spot Price | Premium / Discount | Notes |

|---|---|---|---|

| Dubai | 2,100 | ±0% | LBMA trading hub |

| Switzerland | 2,105 | +0.5% | High purity market |

| China | 2,090 | -0.5% | Large industrial volume |

| Iran/Mongolia | 2,080 | -1 to -5% | Emerging refinery market |

Risk Management & Compliance

Risk Management & Compliance

- Environmental regulations: emissions control, waste disposal

- Safety: chemical handling, furnace operation

- Market risk: price volatility, geopolitical instability

- Certification risk: LBMA approval, traceability

Formula – Projected Profit (Simplified)

Profit = (Refined~Gold~Value - Feedstock~Cost - OPEX - CAPEX\%)/Year

FAQs – Investors & Clients

FAQs – Investors & Clients

-

Can I invest in a small refinery?

Yes, Laka Gold offers partnerships in semi-industrial setups with discounted bullion returns. -

Is LBMA certification mandatory?

For global trade, yes. Regional sales may allow non-certified bars. -

How fast is the refinery ROI?

Typically 1–3 years depending on volume, method, and gold price trends. -

Can electronic scrap be refined?

Yes, via Aqua Regia or Green Refining methods.

Call to Action (CTA)

Call to Action (CTA)

Partner with Laka Gold – Your Gateway to Gold Refining & Investment

- Invest in a gold refinery: Small, Medium, or Industrial scale

- Access discounted bullion (2–50% below global price)

- Participate in regional mining & refining projects

- Contact Laka Gold Team via email, WhatsApp, or our website form

CTA Example:

- Button: “Get Your Custom Refinery Proposal”

- Button: “Download Investor Guide – Gold Refining 202

Gold Bullion Pre-Sale with Special Discount

Top 10 Gold Refineries & Emerging Players Worldwide

Cutting-Edge Gold Refining Technologies | Field Experience & Scientific Insights

Advanced Gold Refining Technologies: From Ore to Pure Gold Bullion

گواهی LBMA و استانداردهای بینالمللی ریفاینری طلا

Global Gold Refinery Directory – Scientific & Practical Reference

The Ultimate Gold Refinery Guide – Largest and Most Complete Gold Refining Reference in the World

Contact Us | Laka Gold – Professional Gold Mining & Refinery Support

LBMA Certification | International Refinery Standards for Gold

100% Pure Gold Bullion – Theoretical 1000 Purity, A First in Refining History

Innovation & Monitoring Department – Submit Your Gold Refining Patents and Ideas

From Mine to Bullion – Practical Gold Refining Process & Industrial Expertise

سفارش طراحی اینفوگرافیک ریفاینری طلا برای پایاننامه و ارائه دانشجویی

درخواست پیشنهاد قیمت ماشینآلات ریفاینری طلا (Gold Refinery Machines)

پتانسیلیابی سریع معادن طلا | روش تجربی و کمهزینه با دقت بالا

Global Gold Refinery Market Report 2025 – Trends, Analysis & Insights

Rapid Gold Prospecting | 1-Day to 1-Week Field Assessment

Rapid Gold Potential Assessment | Low-Cost & High-Accuracy Field Method

Évaluation Rapide du Potentiel Aurifère | Méthode de terrain, faible coût & haute précision

Évaluation Rapide du Potentiel Aurifère | Méthode de terrain, faible coût & haute précision

Gold Refinery Definition: Process, Methods, Models & Global Importance

تعریف ریفاینری طلا و اهمیت استانداردهای بینالمللی (LBMA)

LBMA: Global Gold Refining Standards, Purity Testing & Innovation | Laka Gold

Modern Methods for Testing and Ensuring Gold Purity in Refineries | Accurate Gold Assay Techniques

Gold Refinery: Complete Educational & Investment Guide

Gold Refinery: Comprehensive Guide for Students, Investors, and Freelancers

"Why Gold Refinery Knowledge Remains Private and Its Value for Investors and Students"

? What Are the Duties of a Gold Refinery

? What Are the Functions of a Gold Refinery

Modern Gold Refinery Processes and Production Optimization

Gold Refining Processes and LBMA Standards: Secure Your Investment Opportunity

Gold Mining and Refinery Investment Opportunities with LBMA Purity Guarantee

Investment and International Partnership in Gold Refinery

About LAKA GOLD | Innovative Gold Refinery & Investment Solutions

Gold Assay & Refinery Technology Services (LAKA GOLD)

Gold Refinery Investment & Partnerships (LAKA GOLD)

Advertise on Laka.ir | #1 Global Gold Refinery Portal

Definition of Gold Refinery and the Importance of LBMA – LAKA GOLD

Refining Low-Grade Gold and Concentrates: Methods & Advanced Equipment – LAKA GOLD

Top 10 Gold Refineries & Emerging Players Worldwide

Page Two (Landing Page – Laka Gold)

Laka Gold – Global Partnerships in Gold Mines & Refineries

INNOVATIONS AND ADVANCED TECHNOLOGIES IN GOLD REFINING | PRACTICAL CONSULTING AND SMART INVESTMENT

Inputs & Outputs

Inputs:

- Gold ore

- Gold concentrate

- Scrap jewelry

- Electronic gold

- Unrefined gold bars

Outputs:

- 99.5% gold bars

- 99.99% (Four Nines) bars

- LBMA-certified bullion

- Gold powder and granules

Gold Refinery – Process Description of a Sample Refinery in Iran

Gold and silver extraction from concentrates or gold-bearing cathodes is the primary function of a gold refinery (gold mining factory). A refinery depends on the supply of feed material such as gold cathodes, gold concentrates, molten gold, low-grade gold, or recycled gold artifacts in order to produce high-purity gold bullion.

The refining process usually begins with the weighing and assaying of the input materials. Cathodes or concentrates are measured (typically divided into one-kilogram lots) and their fineness is determined, usually ranging from 995 to 999 purity.

It should be noted that in the jewelry industry, “18 karat gold” is most common, produced by alloying pure 24 karat gold with metals such as copper and nickel. This not only makes the gold harder and suitable for jewelry (rings, bangles, chains, earrings, etc.), but also reduces cost while enabling jewelers to charge for craftsmanship. However, in refining, the ultimate goal is to achieve 24 karat pure gold (999 bullion) by removing impurities such as silver and mercury.

Step 1: Mercury Removal

Gold cathodes often contain traces of mercury. The concentrate is placed in a mercury furnace, where mercury is volatilized and separated. This stage usually takes about 24 hours.

Step 2: Mixer 1 (Acid Dissolution)

The treated material is mixed with an acid solution. Agitation dissolves metals soluble in acid. The slurry is then filtered using a filter press, producing a solution rich in metal sulfates (waste solution) and a solid filter cake containing gold and silver. Duration: ~14 hours

Duration: ~14 hours

Step 3: Mixer 2 (Aqua Regia Treatment)

The filter cake is treated with aqua regia. During this stage, gold dissolves completely, while silver precipitates. After filtration, the filtrate (solution) is transferred to Mixer 3, containing dissolved gold and minor impurities. The filter cake mainly contains silver precipitate. Duration: ~5 hours

Duration: ~5 hours

Step 4: Mixer 3 (Gold Precipitation)

A strong reducing agent is added to precipitate metallic gold from the solution. The gold powder is then separated by filtration and transferred to the smelting section. Duration: ~5 hours

Duration: ~5 hours

Silver Refining

The silver-rich cake from Mixer 2 is mixed with chemicals and melted at over 800°C, producing silver granules or crude silver bars (85–96% purity). These are remelted into anodes and refined electrolytically. Pure silver is deposited at the cathode in powder form, which is later melted and cast into bullion, rods, or granules, according to market demand.

Gold Smelting and Casting

The gold powder from Mixer 3 is melted at over 1000°C. Fluxes are added to remove residual impurities. The molten gold is cast into grain form (gold granules) for accurate weighing. The granules are weighed precisely and divided into 1 kg batches, which are then remelted and cast into standard 1 kg gold bullion bars. Each bar is weighed, stamped, carefully packaged, and delivered to the market.

LBMA – The Global Authority

The London Bullion Market Association (LBMA) is the world’s central authority on physical gold and silver standards.

- Maintains the Good Delivery List for accredited gold/silver refineries.

- Certifies refineries that meet purity, weight, and physical standard requirements.

- Gold Bars: Must be 99.5% minimum purity, weight between 350–430 oz.

- Silver Bars: Must be 99.9% purity.

- LBMA prices (LBMA Gold Price, LBMA Silver Price) are used globally for pricing bullion.

Refineries must be LBMA-approved for their gold to be accepted in global trade.

FAQs – Gold Refining Industry

- What are the major refining methods?

- How does a small refinery differ from an industrial one?

- Where can I buy LBMA-certified gold?

- Is gold refining profitable in countries without local LBMA refineries?

- How long does it take from mine to bar?

Our Mines and Investment Opportunities

LAKA GOLD owns high-grade gold mines in Iran and other regions. Investors can participate in joint projects, acquire high-purity bullion at competitive prices, and engage in two-way service partnerships across refining operations.

INVITATION TO JOIN THE AUCTION OF THE TOP ONE GOLD MINE

Gold Refineries in Dubai

- Emirates Gold Refinery

- Al Etihad Gold

- Kaloti Precious Metals

- Gulf Gold Refinery

All of them are LBMA-compliant and export high-purity bullion.

Full Refinery Process: From Ore to Bar

- Sample Collection: From ore, concentrate, or scrap

- Initial Assay: Fire assay, XRF, ICP

- Pre-Treatment: Drying, milling, homogenizing

- First Refining: Miller process or flux melting

- Final Refining: Electrolysis (Wohlwill) for 99.99% purity

- Casting: Standard molds

- Certification: By recognized assayers or in-house labs

Benefits of Refinery in Iran

- No industrial competitors in the country

- Over 300 producers (jewelry, scrap, workshops) with accessible feedstock

- Large amount of scrap and recycled gold

- High profit margins due to local price gap for unrefined gold

Discounted Gold – 2% to 50%

Investors who participate in supplying gold ore or mining operations can receive refined bullion at discounts between 2% to 50% compared to global rates.

Laka’s Services: End-to-End Gold Solutions

We handle the entire lifecycle of gold:

- Gold exploration and extraction

- Supply of ore and concentrate

- Refinery plant design and operation

- Production of export-ready bullion

Partner with us for mining, refining, and exporting gold.

Suggested Menu for This Page

- What is Gold Refining?

- Scientific & AI Definitions

- Miller & Wohlwill Processes

- Dubai & Global Refineries

- LBMA Certification Guide

- Buy Discounted Bullion

- Contact & Investment Info

Top 10 Gold Refineries & Emerging Players Worldwide

Website: laka.ir

Email: این آدرس ایمیل توسط spambots حفاظت می شود. برای دیدن شما نیاز به جاوا اسکریپت دارید

WhatsApp/Phone: +98-901-665-0528

Tel : +985137665005

GOLD REFINERY DESIGN & ENGINEERING | CLIENT FILTERING SYSTEM | GOLDEN CREDIBILITY SYSTEM (GCS)

Management:Mr. Alireza Sistanizadeh Aghdam

Catalog LAKA GOLD (Download PDF)

-Sample Gold Refinery Contract Download PDF & Word - Mobile

EXCLUSIVE SALE OF THE GOLD REFINERY PLATFORM – TOP-RANKED ON GOOGLE

“Gold Refinery & Polymetallic Exploration Consulting — From Rock to Bullion”

Rent the Top One Google Page – Advertising & Investment

"Advertise with the world’s #1 Gold Refinery Portal – Click here to get started!"