Gold Refinery Project & Investment Opportunities

Introduction

The Gold Refinery Project is one of the most profitable and stable industrial investments in the field of precious metals.

By refining raw or semi-pure gold into high-purity bullion, investors can gain access to both domestic and international markets, while also contributing to economic transparency and value creation.

Gold refining is not only a technical process but also a strategic gateway between mining, trade, and global certification markets such as LBMA (London Bullion Market Association).

What Is a Gold Refinery?

A gold refinery is a specialized industrial facility designed to purify gold from various sources — including mined concentrate, recycled materials, jewelry waste, and semi-pure bullion — into 99.99% pure gold bars that meet international standards.

Main Inputs:

- Gold concentrate (from mines)

- Scrap jewelry and electronic waste

- Semi-refined or low-grade bullion

Final Outputs:

- LBMA-certified gold bars (99.99%)

- Silver, platinum, and palladium byproducts

- Refined gold granules for industrial use

Global Market Overview

The global gold refining industry is estimated at over USD 250 billion annually, with major players located in:

- Switzerland

- Italy

- UAE (Dubai)

- Turkey

- India

- China

However, in Central and East Asia, including countries like Mongolia, Kazakhstan, and Iran, the number of internationally certified refineries is still very limited — creating a golden opportunity for new investors.

Why Invest in a Gold Refinery?

-

High Profit Margin:

Refining adds up to 10–20% additional value to raw gold compared to selling it unrefined. -

Fast Return on Investment (ROI):

Depending on production capacity and location, ROI typically ranges between 18 and 36 months. -

Global Trade Access:

Certified refineries can legally export gold bars to the LBMA or equivalent markets. -

Economic Transparency:

Refinery operation ensures traceability, compliance, and anti-smuggling regulation. -

National and Regional Value Creation:

Developing local refining capacity reduces dependency on foreign refiners and increases internal economic growth.

Refinery Production Capacities

| Type | Daily Capacity | Typical Use | Notes |

|---|---|---|---|

| Laboratory Refinery | up to 5 kg/day | R&D, testing, training | Suitable for universities or pilot projects |

| Semi-Industrial Plant | 5–50 kg/day | Commercial refining | Medium investment, fast ROI |

| Full Industrial Refinery | 50–500 kg/day | Large-scale operations | Requires international certification |

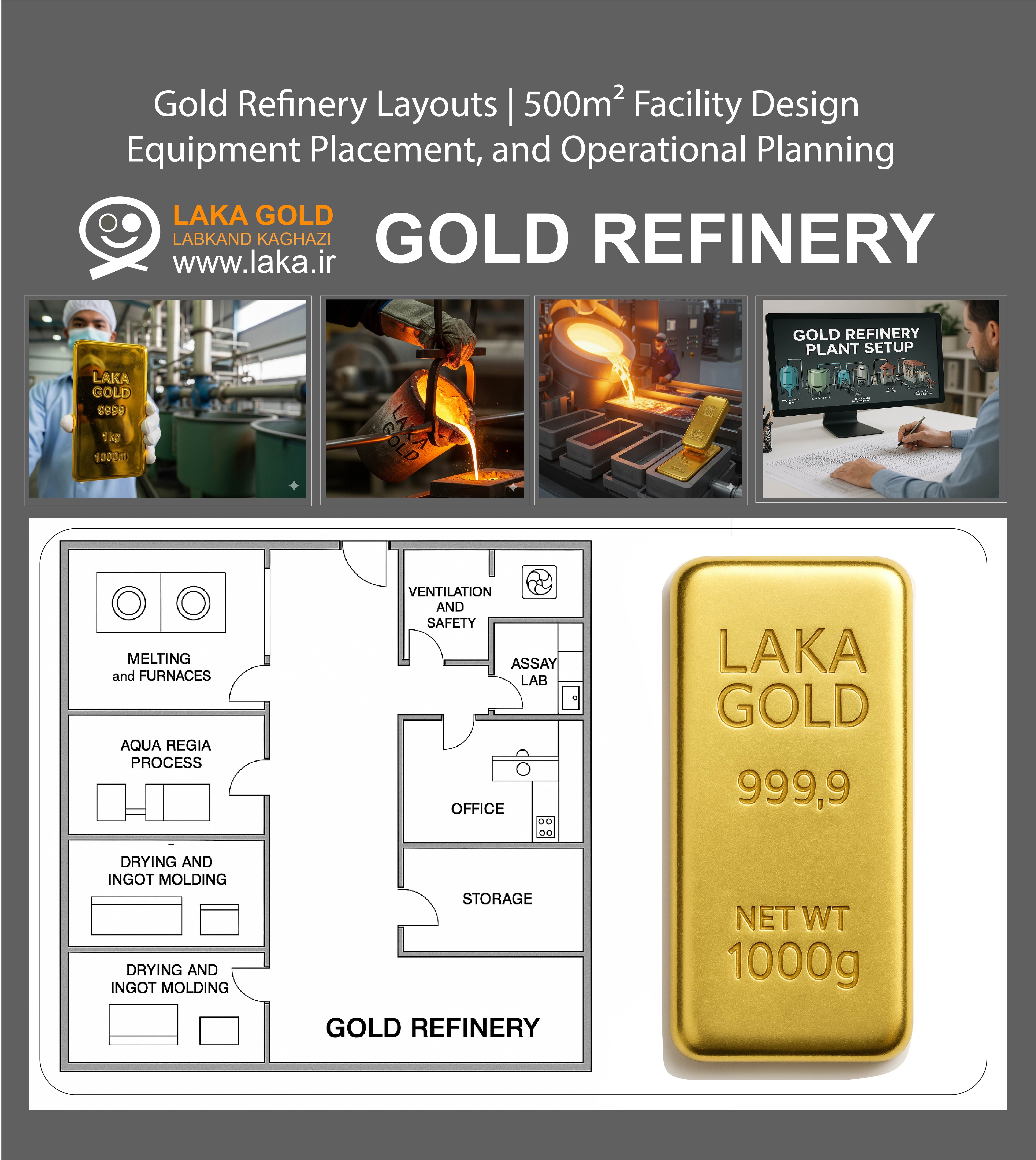

Required Equipment (Standard Setup)

- Gold Melting Furnace

- Acid Dissolution Reactors

- Precipitation and Neutralization Units

- Filtration & Drying Systems

- Electrolysis System (Aqua Regia or Electro-Refining)

- Final Casting and Hallmarking Station

- Laboratory for Assay and Purity Control

- Dust & Gas Treatment Units (Environmental Compliance)

Environmental and Safety Standards

All modern gold refineries must comply with international environmental regulations such as:

- ISO 14001 (Environmental Management)

- ISO 45001 (Occupational Health & Safety)

- REACH and RoHS compliance (chemical safety)

Advanced systems include acid fume scrubbers, water recycling systems, and waste management plans to minimize ecological impact.

Refining Methods

| Method | Description | Purity Level | Application |

|---|---|---|---|

| Aqua Regia | Chemical method using nitric & hydrochloric acids | up to 99.99% | Medium-scale operations |

| Electrolysis | Electrochemical separation method | up to 99.999% | Industrial-grade refining |

| Miller Process | Gas-based chlorination process | up to 99.5% | Initial stage before fine refining |

| Wohlwill Process | Electrolysis with gold chloride electrolyte | up to 99.999% | High-end LBMA standards |

Project Implementation Steps

- Feasibility Study & Market Research

- Preliminary Design & Equipment Selection

- Construction & Installation

- Operator Training & Commissioning

- Quality Certification (Local & International)

- Branding & Export Registration

Example of a Typical Investment Plan

| Phase | Description | Duration | Estimated Cost (USD) |

|---|---|---|---|

| Phase 1 | Feasibility & Design | 2–3 months | 50,000 – 100,000 |

| Phase 2 | Equipment Procurement | 3–4 months | 500,000 – 3,000,000 |

| Phase 3 | Construction & Setup | 4–6 months | 1,000,000 – 5,000,000 |

| Phase 4 | Certification & Operation | 2 months | 50,000 – 200,000 |

Total Average Investment:

Total Average Investment:

$2M – $10M depending on refinery capacity and automation level.

Key Financial Indicators

| Parameter | Value Range | Remarks |

|---|---|---|

| Profit Margin | 8% – 25% | Depends on raw gold purity and yield |

| Payback Period | 18 – 36 months | Based on throughput and gold price |

| OPEX Ratio | 12% – 18% | Operating expenses relative to revenue |

| CAPEX | $2M – $10M | Initial investment including equipment and facilities |

Web : www.laka.ir

Email : This email address is being protected from spambots. You need JavaScript enabled to view it.

Tel : +985137665005

Management:Mr. Alireza Sistanizadeh Aghdam

-Sample Gold Refinery Contract Download PDF & Word - Mobile